Industrial-grade performance. Reliable and repeatable results.

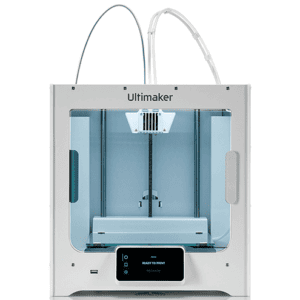

UltiMaker Factor 4, our new industrial-grade 3D printer, streamlines production, simplifies processes, and keeps operations running. With support for engineering materials, direct dual extrusion, onboard print process reporting, and many more innovations, it achieves unrivaled predictability and minimal variance.

The seamless, powerful upgrade that your production workflows demand.

Factor 4 elevates manufacturing with its triple-insulated build chamber and direct dual extrusion. The automated material handling system maintains filament quality. And the robust, temperature-controlled design ensures consistent production output also on complex and challenging designs.

High quality results. Every time. Anywhere.

Achieve the highest print accuracy of any UltiMaker printer – even at high resolution on small design features. These will achieve a dimensional accuracy of ± 0.2 mm ± 0.2% of feature nominal length over the full build plate and across multiple printers.

Success with every 3D print.

Factor 4 makes it possible to additively produce & deploy structural integrity verified parts across different locations. The low variance, less than 10%, in extrusion rate and mechanical properties batch after batch, part after part is a combination of the H-bridge gantry, closed loop feed control, and uniformly controlled build plate temperatures – with a maximum variation of 2 °C across the X and Y axes.

Versatility and quality that translates to fast ROI.

Regular updates ensure that your Factor 4 will evolve over time – far beyond the 12 to 18 months it will take to achieve return on investment. The 3D printer’s modular build allows our global support network to quickly replace parts, minimizing downtime.