HI TEMP 300-AMB is an ultra-high temperature plastic for use in applications requiring high heat resistance. With heat deflection temperature of over 300°C at both low and high stress (HDT at 0.455 and 1.82 MPa), this material is well suited for the testing of high temperature components in applications including HVAC, consumer appliances, motor enclosures, stators, molds and the like. It does not require a secondary thermal post-cure.

Key Material Properties

The full suite of mechanical properties are given per ASTM and ISO standards where applicable. All parts are conditioned per ASTM recommended standards for a minimum of 40 hours at 23 °C, 50% RH. Material properties include physical and mechanical properties, as well as thermal, UL flammability, and electrical (dielectric strength, dielectric constant, dissipation factor, and volume resistivity).

Isotropic Properties

Figure 4 technology prints parts that are isotropic in mechanical properties meaning the parts printed along either the XYZ axis will give similar results. Parts do not need to be oriented to get the highest mechanical properties, further improving the degree of freedom for part orientation for mechanical properties.

Long term environmental stability

HI TEMP 300-AMB is engineered to give long term environmental UV and humidity stability. This means the material is tested for the ability to retain a high percent of the initial mechanical properties over a given period of time. This provides real design conditions to consider for the application or part.

The chart shows a sampling of the dataset. The full datasheet includes Indoor and Outdoor Stability data for Tensile Strength, Elongation at Break, Tensile Modulus and Impact Strength. Actual data value is on Y-axis, and data points are % of initial value.

Applications

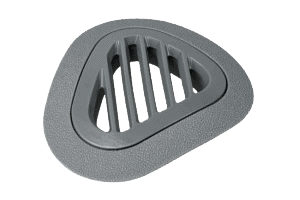

- High temperature components testing, and general use parts including: HVAC, consumer appliances, motor enclosures, stators, etc.

- Low pressure molding/tooling: expanding foams, rubbers, etc.

- Overmolding

Benefits

- Production-grade material

- High heat resistance for testing and use in high heat environments

- No secondary thermal post-cure required

- Excellent visualization for parts requiring evaluation of internal features and fluid flow performance

Features

- HDT over 300 °C at both low and high stress (HDT at 0.455 and 1.82 MPa)

- Rigid and translucent

- High tensile modulus for use in molds (4000 MPa)