Tough 60C White is a versatile, biocompatible-capable production-grade white material with good impact strength, elongation, and tensile strength. It provides long-term environmental stability and long-lasting white color with an injection molded-like surface quality. This material is recommended for high mechanical load-bearing batch production medical parts that remain functional and stable for years.

This resin features a 65˚C heat deflection temperature and 23% elongation at break and is excellent for brackets, snaps, and clips due to a 7.1% elongation at yield. Fast print speeds and simplified post-processing speeds enable exceptional throughput.

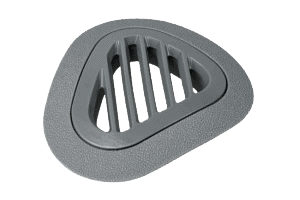

Figure 4 Tough 60C White is tested to 8 years of indoor and 1.5 years outdoor mechanical performance per ASTM D4329 and ASTM G194 methods, ensuring that printed parts remain functional and stable for long periods in real-world conditions.

Material Properties

The full suite of mechanical properties is given per ASTM and ISO standards where applicable. All parts are conditioned per ASTM recommended standards for a minimum of 40 hours at 23 °C, 50% RH. Material properties include physical and mechanical properties and thermal, UL flammability, and electrical (dielectric strength, dielectric constant, dissipation factor, and volume resistivity).

Isotropic Properties

Figure 4 technology prints parts that are isotropic in mechanical properties meaning the parts printed along either the XYZ axis will give similar results. Parts do not need to be oriented to get the highest mechanical properties, improving the degree of freedom for part orientation for mechanical properties.

Applications

- Clinical trials and medical devices such as tools, handles, and small plastic parts

- Load-bearing parts such as handles, cranks, knobs, and levers

- Structural parts like brackets, snap-fits, and custom fasteners

- Small parts requiring detail and accuracy in consumer products, wearable devices, and general use

- Functional prototyping and biocompatible end-user parts

Benefits

- Long-term use parts for indoor and outdoor applications

- No secondary thermal cure required

- Clean, long-lasting bright white color

- Excellent surface quality, accuracy & repeatability

- Autoclavable

Features

- Long-term indoor and outdoor environmental stability of mechanical properties and color; tested out to 8 and 1.5 years (respectively) per ASTM methods

- Biocompatible-capable per ISO10993-5 and ISO10993-10*

- 65°C HDT at 0.455MPa

- 23% elongation at break

- 7.1% elongation at yield

- 34 J/m notched impact strength

- 1500 MPa tensile modulus

- UL94 HB flammability

- Sterilization through Autoclave